Tel: 13807296531

0712-5259111

Fax: 0712-5259166

E-mail: hbanliang@126.com

Post Code: 432600

Address: No. 66 Jiefang Avenue East Road, Anlu City, Hubei Province

Tel: 13807296531

0712-5259111

Fax: 0712-5259166

E-mail: hbanliang@126.com

Post Code: 432600

Address: No. 66 Jiefang Avenue East Road, Anlu City, Hubei Province

summary

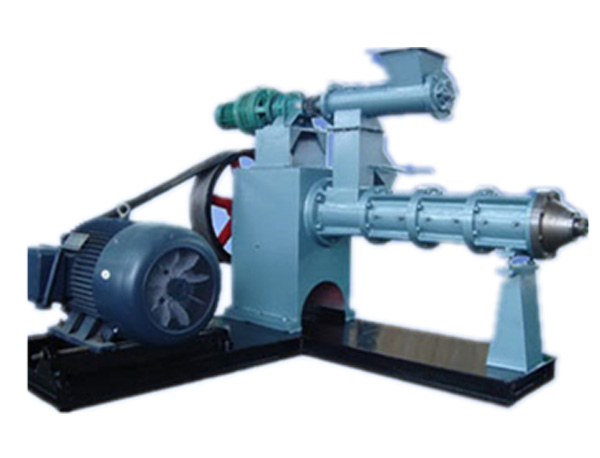

TXP-160 extruder can be expanded rice bran, soybeans, corn, rice flour and feed and other materials, suitable for oil, rice plant, soybean protein plant and feed factory processing. The machine production capacity, low power consumption. Puffed rice bran can keep fresh for more than two months, the leacher production capacity increased by 30 ~ 45%, dry residue less than 1% residual oil, fur meal protein content, color are better than granulation drying leaching. Expanded soybean can be deodorized, passivation of urease, leacher production capacity increased by 45 ~ 50%, dry residue less than 0.8%, soybean meal protein content and color is better than dry leaching.

Extrusion principle

The machine is the use of non-equidistant spiral extrusion, friction, shear and so on, so that mechanical energy into heat, and in the expansion of the cavity to form a certain pressure and temperature, so that the material out of the material die extrusion molding.

Use characteristics

First, the application in the oil plant (with 15T / D oil plant supporting)

Expanded leaching process made of oil color light, low acid prices, easy to produce various grades of high-level edible oil.

1, rice bran puffing oil extraction process:

Rice bran → clean → puffing preservation → leaching oil.

Through the puffing of rice bran, store an average monthly acid price rise of about 1mgKOH / g oil.

2, soybean puffing oil extraction process:

Soybean → clean → softening → rolling billet → puffing → leaching.

Second, in the application of soy protein plant

Soya → clean up → soften → billet → puffing deodorization passivation urease → degrease → soy protein.

Ureaase activity index after soybean puffing UA <0.4.

Third, in the rice plant in the application of the process (with 200T / D meters supporting more than rice)

Raw grain → clean up → hulling → deep separation of rice → rice → rice bran → puffing shaping preservation → finished rice bran → packaging → to the oil plant or feed workshop.

Fourth, with the feed plant in the application

Soybean → Broken → Expanded Dilute Maturation → Make Formula Feed.

The machine in the above applications, according to a variety of puffing requirements, the temperature in the range of 80 ~ 140 ℃, the pressure in the range of 2 to 4 atmospheric pressure, through the replacement of the die or adjust the die and extrusion head Between the distance to achieve; puffed material can be dehydrated 3 ~ 5%.

The main technical parameters

1 processing capacity kg / h rice bran 800 ~ 1000 soybean 1100 ~ 1400 feed 800 ~ 1000

2 spindle speed r / min 630

3 feed speed r / min 200 ~ 400

4 main motor power kw 55

5 feed motor power kw 2.2

6 electricity consumption kw · h / t rice bran <45 soybean <35 feed <40

7 Noise dB (A) <80

8 Processing temperature ℃ 80 ~ 140

9 Dimensions (L × W × H) mm 2150 × 2100 × 1280

10 machine weight kg 1800

This information is for reference only, the specific parameters and functions, please refer to the instructions.

The site may create a slight difference between the product and the material.